We focus on providing efficient vacuum casting solutions for the product development stage, using silicone mold technology and multi-material adaptation technology, with a minimum order quantity of 50 pieces, suitable for functional verification and market testing in the fields of consumer electronics, automotive parts, cultural and creative products, etc.

Specifications

Benefits & Features

Core advantages

Professional technical team

We have an experienced team of professional technicians to carefully serve each customer.

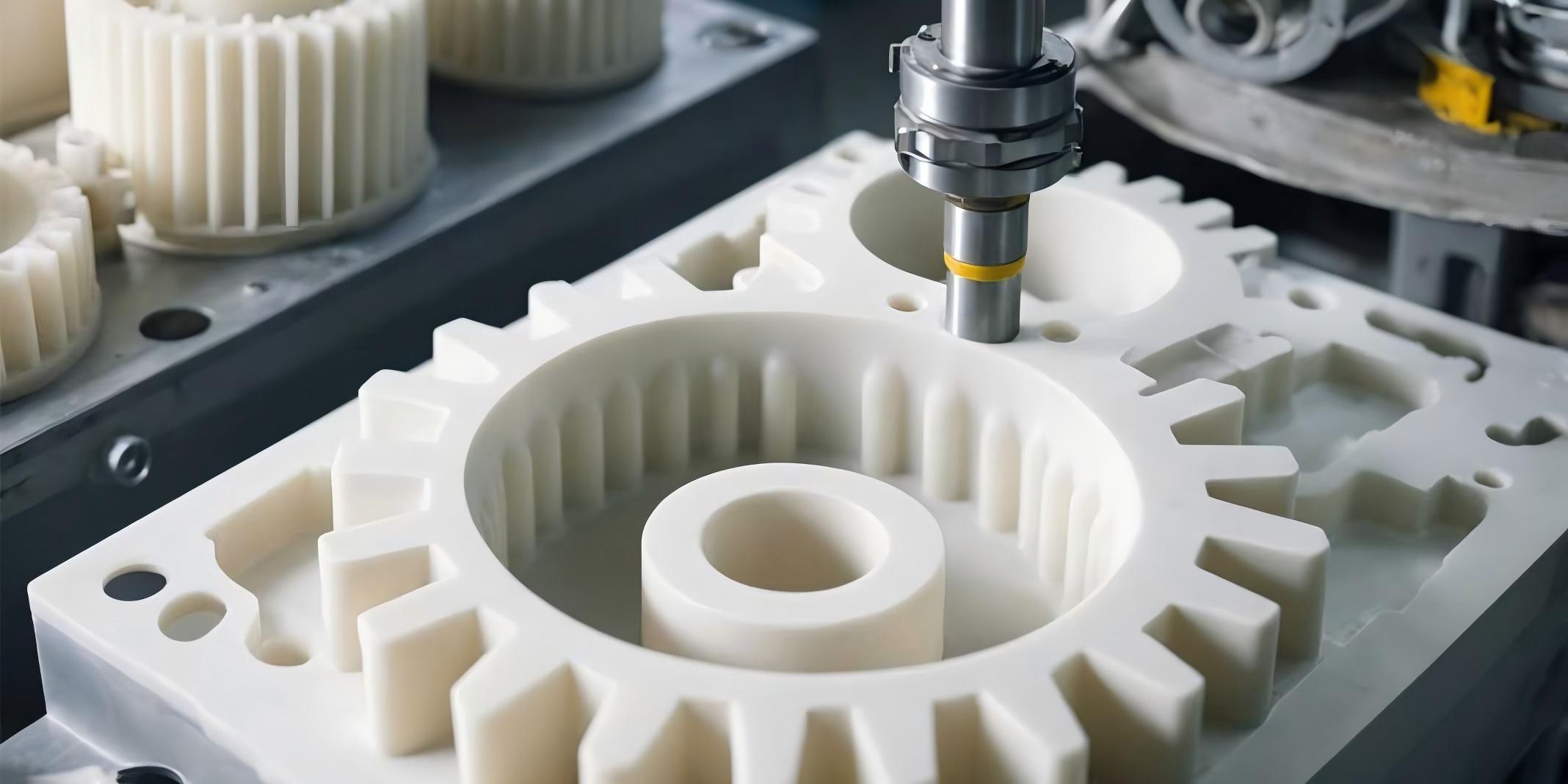

Advanced processing equipment

The factory is equipped with advanced processing equipment to ensure the quality of customers’ products and reduce delivery time.

Low-cost trial and error solution

The mold cost is only 10%-20% of the steel mold, supporting a single order without mold fee sharing, and the trial production cost is reduced by more than 60%.

Flexible material adaptation

Compatible with 60+ engineering resins such as ABS (impact resistance), PC (high transparency), PP (chemical corrosion resistance), etc., supporting special effects such as matte, metallic texture, and soft touch.

Applicable fields

Consumer electronics

Smart wearable device housing, TWS headset charging case, button silicone gasket

Automotive parts

Interior panel prototype, sensor shield, wiring harness connector cover

Industrial design

Product appearance verification model, ergonomic handle, structural assembly test piece

Cultural and creative products

Limited edition crafts, IP derivatives, customized gifts

Technical capabilities

Processing accuracy

Dimension tolerance ±0.1mm, surface roughness Ra≤1.6μm, can reproduce 0.2mm fine texture

Equipment parameters

Vacuum casting machine vacuum degree ≤1mbar, constant temperature curing box temperature control accuracy ±2℃

Mold life

A single set of silicone molds can produce 20-50 pieces, supporting 3 design iterations of the same mold

Quality control

First piece full inspection: three-coordinate measuring machine detects key dimensions (accuracy ±0.02mm)

Batch sampling: 10% of each batch is randomly selected for assembly testing and appearance inspection

Special tests: support flame retardancy (UL94), light transmittance (ASTM D1003), hardness (Shore A/D) and other customized tests