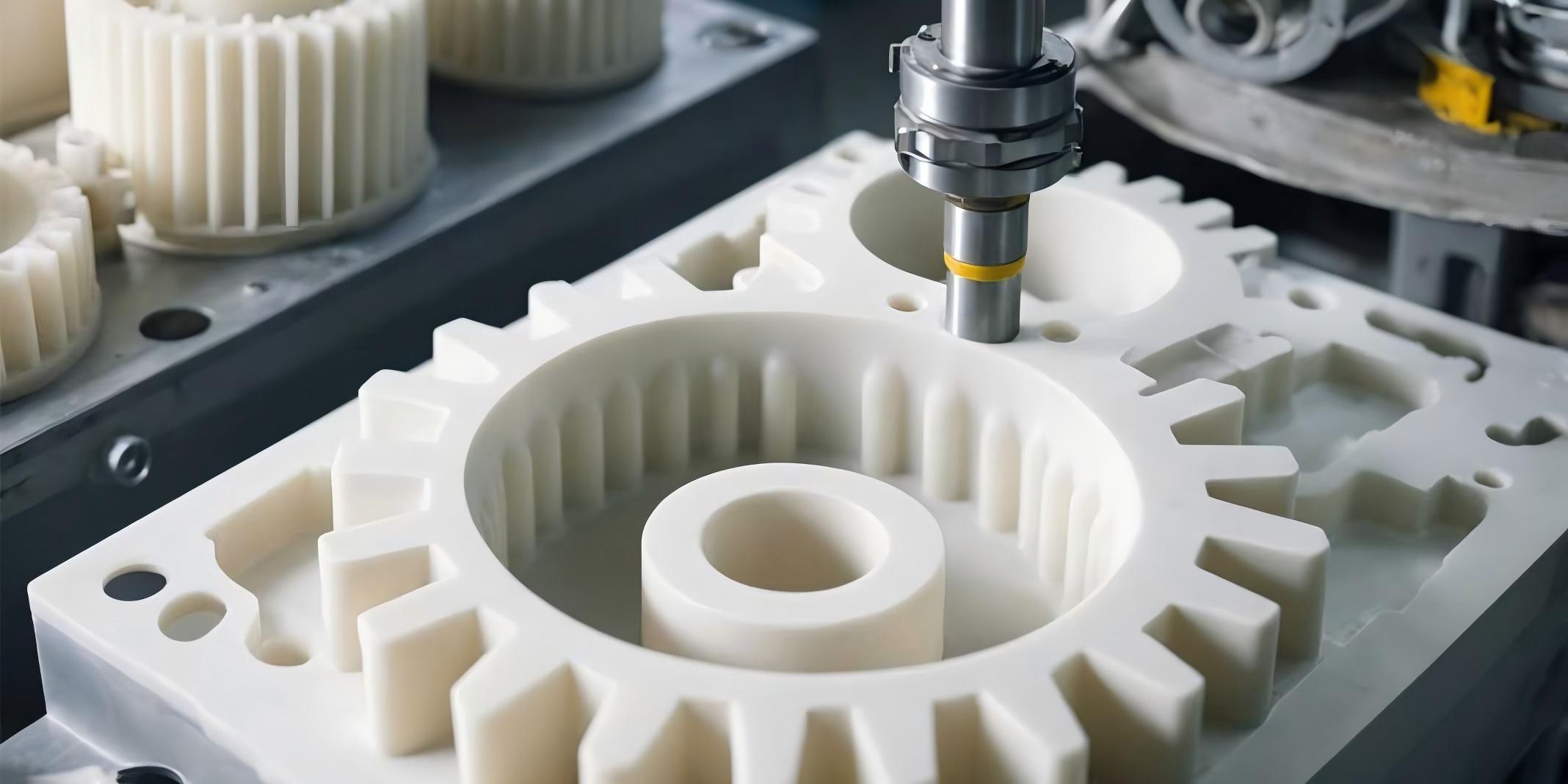

We focus on the silicone mold vacuum casting process, and achieve rapid prototyping and small-batch production with a dimensional tolerance of ±0.05mm through high-precision mold technology. It is suitable for functional verification and market testing in the fields of automobiles, medical care, electronics, etc., and supports transparent, flexible, high-temperature resistant and other characteristic materials. The life of a single silicone mold can reach 50-100 pieces.

Specifications

Technical parameters

Equipment configuration

Vacuum casting machine: vacuum degree ≤0.8mbar (German Kurtz Ersa system)

Constant temperature curing box: temperature control ±1℃ (20-80℃ adjustable)

Silicone mold hardness: Shore A 20-40 (select according to the complexity of demolding)

Processing range

Maximum size of a single piece: 600×400×300mm

Weight of a single pouring: 0.1g-5kg

Standard delivery cycle: 3-7 days (including post-processing)

Benefits & Features

Core capabilities

Ultra-fine reproduction

Surface detail resolution: 0.02mm (fine textures and micro-holes can be reproduced)

Minimum wall thickness: 0.3mm (transparent parts without bubble defects)

Mold production cycle: 24-48 hours (3 times faster than CNC processing)

Material diversity

Engineering plastics: ABS-like (impact-resistant), PC-like (high light transmittance), PP-like (chemical corrosion resistance)

Elastomer: Shore A 10-90 hardness adjustable (simulating rubber/silicone touch)

Special materials: high temperature resistant resin (180°C continuous working temperature), conductive composite materials (surface resistance <10Ω)

Industry certification

Medical grade: ISO 10993 biocompatibility certification (cytotoxicity test passed)

Automotive grade: meets GMW3059 flame retardant standard (UL94 V-0)

Food grade: FDA 21 CFR certification (food contact safety)

Typical applications

Precision industrial parts

Gearbox functional prototype (alternative metal die-casting verification)

Sensor waterproof housing (IP67 sealing test)

Micro connector (0.4mm pin pitch reproduction)

Medical and optical equipment

Endoscope bending joint prototype (200 motion cycle test)

Light guide diffusion structure (transmittance>92%)

Prosthetic silicone lining (Shore A 30 hardness bionic touch)

Consumer electronics verification

Smart watch case (metal texture electroplating effect)

TWS headset charging case (500 opening and closing life test)

Button silicone gasket (0.1mm concave and convex texture reproduction)

Quality control

First piece full-size inspection: three-coordinate measuring machine (accuracy ±1.5μm)

Material performance verification: tensile strength/elongation at break/thermal deformation temperature test

Silicone mold life monitoring: record detailed loss rate for each mold, and early warning replacement

Common questions

What is the minimum order quantity?

Supports 1 piece minimum order, and 50 pieces or more can enjoy unit price gradient discounts

Can the internal bubble problem of transparent parts be reproduced?

Use secondary vacuum degassing process to ensure that the haze value of transparent parts is <2% (ASTM D1003 standard)

What are the options for surface treatment?

Supports sandblasting (Ra 1.6-6.3μm), UV coating (hardness 3H), pad printing (positioning accuracy ±0.1mm)